- #Modbus server and device not communicating drivers

- #Modbus server and device not communicating driver

With these PLCs, the simultaneous interoperability of different PLCs in industrial systems has been demonstrated. Speed control of the conveyor belt is achieved with the help of an Open Platform Communications Unified Architecture (OPC UA) server using multiple Programmable Logic Controllers (PLC) and Proportional-Integral-Derivative (PID) controller algorithm. Make sure to test a few tag values when you get the Address Mapping set up, Modbus devices cannot verify that your mapping is correct, it just creates a list of tags for you.In this study, it is aimed to control the speed of a conveyor belt system based on the principles of observation, control, data storage and data transfer between systems, which became widespread with Industry 4.0. Once you have your mapping set up, just drag your Tags into Ignition and start designing. You can even import and export your maps to make it quick and easy to set up many devices. Address MappingĬreating an Address Map in Ignition for your device allows you to drag and drop tags just like any of the browseable device connections (like an AB Controllogix). It's that simple! Try setting up HR0, HR1, and HR2 while you are testing to help figure out your conneciton settings. If you want to look at Holding Register 1 (a common address in Modbus), the OPC Item Path is "HR1". Manually creating Tags in Ignition is pretty easy. If you leave it at 1, this will cause a huge strain on your system after you have added hundereds or thousands of tags from your device. Change this setting (under the Advanced properties) to 1 while you are testing, and set it back when you are done. This setting can cause all of your test tags to go to bad quality when only one is bad. One important setting to note is the Max Holding Registers Per Request.

It's helpful to manually create a few Tags in Ignition and change your connection settings until your values are correct. For example, you could have 0/1 based addressing or reversed word order that isn't clearly documented in the device instructions.

Getting access to your Modbus tags can be confusing because of all the different options available in the device connection. The great part is that you can just try both and see which works! If you're not sure which connection type to use, it's probably not RTU.

#Modbus server and device not communicating driver

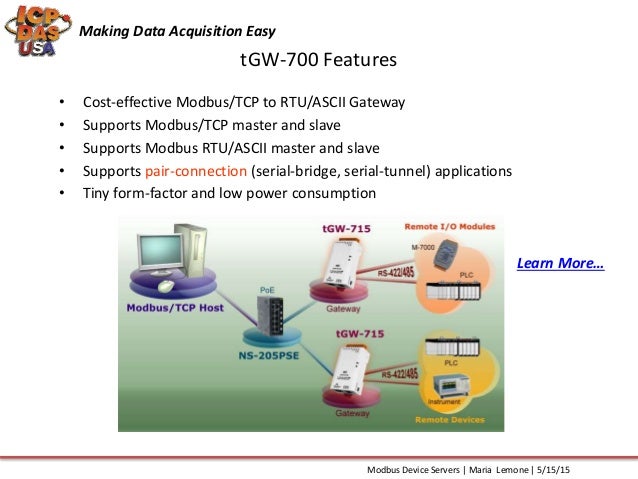

Because of this, the Modbus driver can connect directly to any devices that support Ethernet communications, even if they use the older RTU standard. Our generic Modbus driver allows the Ignition OPC-UA server to communicate with any device that supports the Modbus TCP protocol or the RTU over TCP protocol. The main idea behind the Modbus standard is that you should have a regular pattern for tags inside the device, and use the same connection methods. This is a huge benefit, but can lead to a lot of confusion because different device manufacturers may design their devices differently, and the documentation for the different manufacturers varies wildly in quality and availability. Modbus is a protocol used for connecting to many types of devices.

#Modbus server and device not communicating drivers

Unlike some of the other drivers (like Allen Bradley, Siemens) Modbus is a standard and not specific to a brand of device.

0 kommentar(er)

0 kommentar(er)